Mural Brings Fresh Life to Wessels Company headquarters

September 2020

Contact: Rebecca Bennett- Marketing Coordinator

[email protected]

317-888-9800

For Immediate Release

Mural Brings Fresh Life to Wessels Headquarters

GREENWOOD, IND. — Wessels Company has announced that the large-scale, outdoor mural at their headquarters in Greenwood, Indiana is complete. It took just over a week for the sketching and painting to be completed on the 100-foot by 20-foot wall.

The mural depicts the company’s logo as well as its products, like air and dirt separators and expansion tanks, which are manufactured at the factory. From concept to final design, some changes were made in collaboration between Wessels Company and local artist Macey Dickerson.

“When [Wessels] initially sent me reference photos to incorporate into the mural design, the expanded view of the heat exchanger really caught my eye,” Dickerson said. “It was such a cool diagram and I knew I wanted that the be a prominent feature. I really like how that part looks.”

She added, “Painting the Wessels logo was also really fun. I like how the curviness of the font contrasts nicely with the rest of the mural, which is more geometric.”

Dickerson was assisted in painting by her brother, Garrett Dickerson and her friend, Nick Service. “I enjoyed the process of working with my brother and friend who helped me bring the design to life,” Dickerson said. “I usually do projects solo, so it was fun working in a team and sharing the experience. I also enjoyed getting to meet the employees at Wessels. Everyone was so friendly and supportive! When it was break time, people were sure to stop by and say ‘hi’ and give encouragement. I felt so welcome.”

Jim Fuller, president of Wessels Company, says he is pleased with how the mural turned out.

“It adds color and art to the neighborhood,” Fuller said. “It also conveys our pride in our products, our employees, and being part of the Greenwood community.”

###

We are pleased to welcome Michele Curtis as the newest member of the Wessels team, joining our inventory department at the start of September. Michele brings a strong educational background from Ivy Tech, where she studied business and mathematics, along with several years of managerial experience in manufacturing at a snack company. Outside of work, she enjoys outdoor activities, weekend road trips, and fishing with her husband, as well as spending time with her granddaughter and watching football and baseball. An interesting note about Michele is that she is left-handed. Her colleagues, who share an office with her, appreciate her positive demeanor and ability to uplift the workplace atmosphere.

We are pleased to welcome Michele Curtis as the newest member of the Wessels team, joining our inventory department at the start of September. Michele brings a strong educational background from Ivy Tech, where she studied business and mathematics, along with several years of managerial experience in manufacturing at a snack company. Outside of work, she enjoys outdoor activities, weekend road trips, and fishing with her husband, as well as spending time with her granddaughter and watching football and baseball. An interesting note about Michele is that she is left-handed. Her colleagues, who share an office with her, appreciate her positive demeanor and ability to uplift the workplace atmosphere.

“I kind of don’t remember a time when I wasn’t painting,” Dickerson says. She works in a wide variety of mediums –clay, photography, digital art –but says she loves painting the most.

“I kind of don’t remember a time when I wasn’t painting,” Dickerson says. She works in a wide variety of mediums –clay, photography, digital art –but says she loves painting the most.

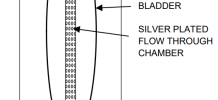

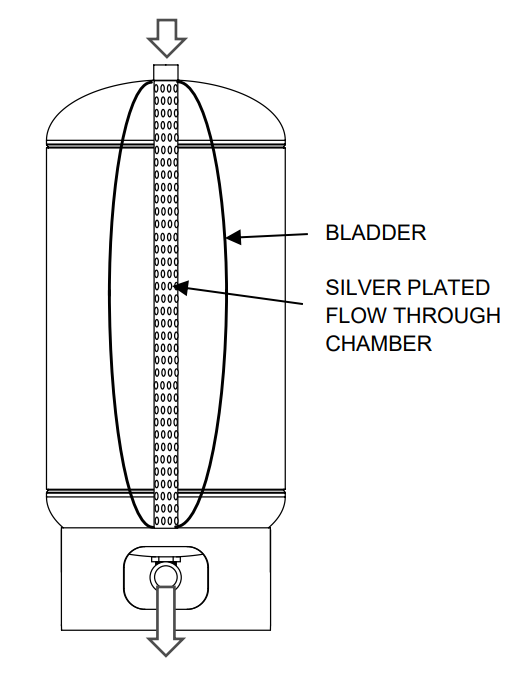

Expansion tanks have been established as a place where pathogens like Legionella can flourish. The new TTA-Rx Full Flow tank features a perforated internal that disrupts stagnant water with a flow-through design. In addition, silver plating or other antimicrobial coatings are applied to the internal to create a surface that can destroy harmful microbes through contact. Unlike normal rubber, the heavy-duty butyl bladder also does not support the build-up of nutrients key to forming biofilms.

Expansion tanks have been established as a place where pathogens like Legionella can flourish. The new TTA-Rx Full Flow tank features a perforated internal that disrupts stagnant water with a flow-through design. In addition, silver plating or other antimicrobial coatings are applied to the internal to create a surface that can destroy harmful microbes through contact. Unlike normal rubber, the heavy-duty butyl bladder also does not support the build-up of nutrients key to forming biofilms.