How To: Understanding the Makeup of Glycol Makeup Packages

How To: Understanding the Makeup of Glycol Makeup Packages

Wessels Company makes Glycol Makeup Packages in Glymatic, Single, Double, and Twin systems. The purpose of a GMP is to maintain system pressure.

In the sequence of operation in a system using a GMP, the glycol solution mixture is held in a solution container and then is pulled through a pump. The pump has an internal spring that utilizes a pressure relief valve, if the pressure in the system is too high. Fluid goes into the pump, the pressure is increased with a rotary vane, and then is discharged into the system at a higher pressure.

The package is protected by a low water cutoff probe in the solution container. Two probes are in the container and monitor the glycol mixture

level. If the level falls too low, the continuity between the offset probe is broken and the pump is shut off, which sounds an alarm.

The pump is controlled by a pressure switch, which is set to turn on at 60 psi and to cut off at 80 psi. The 80 psi of fluid is then stored in an expansion tank to hold the excess fluid. The expansion tank is a diaphragm tank that has a pre-charged pressurized air cushion, which helps maintain the pressure in the system to 80 psi.

The fluid then flows through a pressure reducing valve or PRV, which is set for the system’s required pressure. The valve’s range can go from 10 to 70 psi, which can be for whatever pressure your system needs.

Inside the PRV, a spring sets the tension that holds the valve open. The valve can be set to point downstream between 10 and 70 psi, the spring will hold the valve open until the downstream pressure equalizes the spring tension through the diaphragm, that will hold the diaphragm up and close the valve.

Wessels Company offers four different types of GMP systems: a glymatic, a single, duplex, and twin. A Glymatic system package is a free-standing solution reservoir that holds the glycol/water solution at atmospheric pressure. A pressure assembly is mounted on the solution reservoir’s cover keeping the pressurization unit off the floor. This GMP uses a pressure station to move fluid from a 6 or 15-gallon reservoir pressurized to between 1 and 25 psi, up to 130° F. The solution then remains stored until it is needed to replenish the system that has lost its glycol/water or water solution.

The single system GMP automatically services one closed-loop system. This GMP holds a reservoir of 50 or 100-gallons and 1/3 and 1/2 horse power pump pressurization control station with magnetic starter. The 1/3 HP is used for systems of 50 PSI pressure and the ½ HP station is used for systems up to 70 PSI.

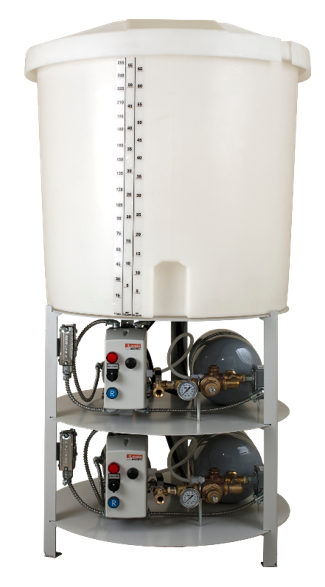

The Duplex system or GMPD, services two separate closed-loop systems. This system is available with 50- or 100-gallon reservoir and 1/3 or ½ HP pump pressurization control also with magnetic starter.

The Twin system or GMPT also services one closed-loop system and is available with the 50 or 100-gallon reservoir with 1/3 or ½ HP pump.

However, a control panel with alternator and dual magnetic starter is used with this system to easily and automatically alternate between two pumps.

To see exactly how the GMP system works, you can watch our technical video, here.

You can also learn more about the GMPs, on our website, here.