How To: Understand Pre-Charge in Bladder Tanks

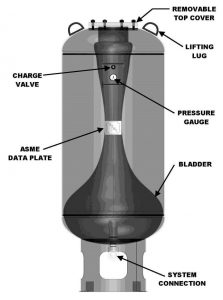

Pre-charged diaphragm and bladder tanks are necessary to protect systems from excessive pressure, energy, or water in a variety of scenarios. In this blog, we will discuss why you need to pre-charge, how to decide pre-charge settings, and the maintenance that should be done on this type of tank.

Pre-charge pressure is needed for bladder tanks which are used in HVAC domestic hot water, water well, pressure booster, and shock and surge applications. An engineer or maintenance person must first determine the application and pressure requirements of the system to determine the pre-charge setting.

For domestic water heating systems, the thermal expansion tank is positioned between the cold-water supply to the building and the water heater. The pre-charge pressure is set to equal the cold-water static or no flow condition. For example, if the supply line pressure is 60 psi, the pre-charge within the expansion tank should be set to 60 psi. As water flows, the flow pressure drops below static pressure. Thermal expansion protection is not needed since the expanded water is leaving the plumbing system. As flow stops and static pressure returns to the system, the pre-charged expansion tank is fully engaged to handle the expanded water.

A shock and surge arrestor accepts water at the quick closing valve to help dissipate the kinetic energy from the suddenly stopped water column. When water flows, every foot per second water flow velocity creates 65 psi of increased pressure over static. This spike will occur within a millisecond if the water is stopped suddenly. The kinetically created pressure reverberates through the pipe by increasing the pipe diameter to the point of relief, and as the pressure wave is reflected and returns, it constricts the pipe.

Most flow going through a pipe will be between 4 and 8 feet per second which equates to an increase of 260 to 520 psi. The pre-charge pressure for the arrestor should be set 10% below the flow pressure. The shock arrestor absorbs the excess pressure from the sudden energy surge. The pressure will equalize due to the energy absorption within the pipe. Instead of the buildup of the pressure damaging the pipe, the shock and surge arrestor takes the brunt of the pressure to ensure the safety of the pipe.

For a water well tank, or hydro-pneumatic system, a pressure switch controls the pump. The switch is normally set to a differential of 20 psi between the minimum required pressure for the building and the high pressure dictated by the switch. A home’s water well system is normally set to 2 psi below the pump cut-in to maximize the water stored, thus resulting in the longest pump run-time which helps extend the life and power of the pump. Within a commercial building, the normal pre-charge is set 10% below the pump cut-in pressure.

Yearly preventative maintenance should be completed to ensure your bladder or diaphragm tank is holding its pre-charge and thereby providing necessary system protection. The process of checking the tank begins with isolating the vessel from the system. A drain should be installed between the system isolation valve and the tank. If no drain is present, identify another means of discharging water from the tank. Often a plumbing union can be loosened to drain the tank water.

Check the pre-charge pressure and add pressure if needed. Note, it is best to keep the drain open when re-charging the tank so you can determine if air is passing through the bladder/diaphragm and leaving through the drain. If this occurs, the bladder/diaphragm is compromised.

Preventative maintenance will help extend the life of the tank and the bladder. It is important to check areas within the tank that might be subject to loss of pressure or air, such as any tapings or seams on the tank that may have corroded, or a malfunctioning air valve or plug. It is also important to remove the water from the bladder once a year to ensure there are no loss of pressure issues with the tank.

The pre-charge tank function ensures a minimum pressure. A designer will typically determine this based on building height, minimum pressure needed at each fixture, or what will result in the greatest system protection.

To learn about correctly sizing an expansion tank, check out this related article: