How To: Check and Repair Leaks at the Bottom System Connection of an Expansion Tank

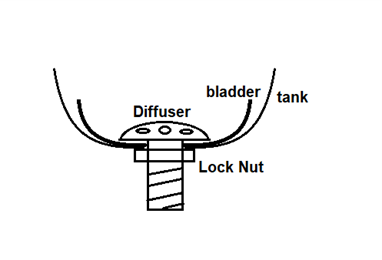

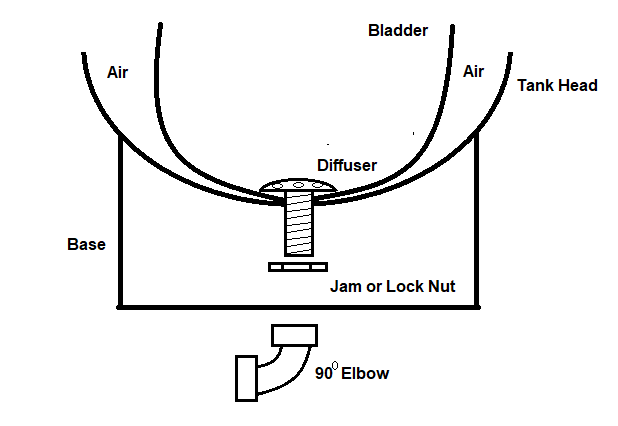

Expansion tanks sometimes develop air, liquid, or weeping water leaks at the bottom system connection (BSC). The BSC is a bulkhead fitting the goes through the tank bladder and compresses the bladder to the bottom tank head with the tightening of a jam or lock nut. The locknut is the sealing force between the tank head and the internal bulkhead threaded connection.

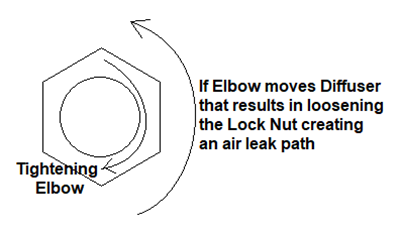

The elbow is tightened to the NPT threads of the diffuser. If there is torque created by piping into the elbow, this can cause misalignment and a subsequent air or water leak. To test the tank, first remove the potential torque.

1. Isolate tank from system.

2. Drain water from bladder (ideally there is a drain between the shutoff and the tank.)

3. Break the union to the tank (again, ideally between shut off and tank).

4. Charge air pressure to required pre-charge.

5. Apply soapy solution on lock nut. Tighten until there are no air bubbles.

6. Place piping into union to reintroduce torque (if there was any to begin with).

7. Apply soapy solution to lock nut again. Tighten until there are no air bubbles.

8. Service tank back into operation.

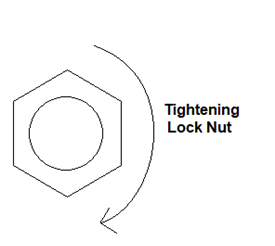

The tightening of the lock nut is in a normal clockwise manner that draws the diffuser down to compress the bladder. The elbow is then threaded to the NPT threads of the diffuser. If the elbow and diffuser spin freely, it has the same effect as loosening up the lock nut. This loosening will result in loss of air charge. The lock nut will require retightening to 60-70 ft-lbs. to re-establish the seal.